making the digital world a safe(r) place

making the digital & industrial world a safe(r) place

nothing more, nothing less

nothing more, nothing less

One organization at a time

Starting with yours

Our Services

This wheel represents the integrated ways we secure your digital and industrial assets. Our end-goal is your autonomy, by empowering you with lasting internal capabilities. Our main service categories are Thinking, Doing, and Training—complemented by the cross-cutting disciplines of Demystifying, Architecting, and Coaching that connect and enhance each core service. (For more info, check our FAQ.)

Training: Build Lasting Capability

We empower both leadership and OT and IT teams with cybersecurity awareness and expert guidance. Our (C)ISO and E(S)A trainings aim to cultivate the internal cyber-defence capability; turning internal candidates security officer or architect into confident security professionals. Transferring knowledge, not on keeping you locked-in.

Demystifying: Where Training & Thinking Overlap

We strip away the jargon from legislation and frameworks so executives and their teams truly understand digital business outcomes and its darker backside cybersecurity in their specific business context.

Thinking: Plan Before You Act

We analyse your business context and assess risks to design a tailored security maturity and technology roadmap. Thoughtful planning ensures that your investments in cybersecurity are effective and aligned with your digital & business objectives. Based on frameworks like ISO27001, ISO/IEC 62433, CIS controls, NIST CSF, CRA ...

Architecting: Where Thinking & Doing Overlap

From bottom up Secure Network Design to holistic Enterprise (Business, Security and Technology) Architectures, or even designing IT & Cyber Operating Models.

Doing: Make Security Real

We implement and populate your Information Security Management System (ISMS), develop policies, conduct threat and risk assessments, and provide ISO/DPO/Enterprise (Security) Architect-as-a-Service when needed. We also test your defenses through penetration testing and ethical hacking. Seeing is believing—we challenge your systems to prove they actually work.

Coaching: Where Doing & Training Overlap

Hands-on guidance as you build and run your security processes and controls. We stand shoulder-to-shoulder with your internal architects, security officers, and even OT/IT partners—coaching them through real-world implementation challenges rather than just documenting what should be done.

Tooling: Governance process management made 'easy'

You can subscribe to our templated governance and workflow platform, or we design an ISMS blueprint within your existing document or service system to safeguard your security knowledge and support your internal security capability. In our preferred platform we offer templates for general GRC or specific ISO27001, NIS2 and IEC 62433.

Our Values

Trustworthy & Discrete

We protect our clients confidentiality and handle sensitive data with the utmost care. Our clients trust us with their security. This may sound obvious, but sometimes the obvious needs to be said.

Ambidextrous

Literally it means 'able to use both right and left hands equally well'. We see it as a personal and organisational value to be able to look to each challenge or risk in both technical and business-economical terms.

Open minded & Curious

We embrace new perspectives and question assumptions, even our own, as we enter each time a new business context with specific risks & challenges, and where we meet new people and personalities in this fast changing world.

Sharing

We openly exchange knowledge, insights, and experiences across our team and with clients. Security is stronger when we learn together - we believe in collective growth over siloed expertise.

Contact Us

Have questions or want to schedule a meeting? Feel free to reach out through our contact form, or check our FAQ for instant answers to common questions.

Contact Us

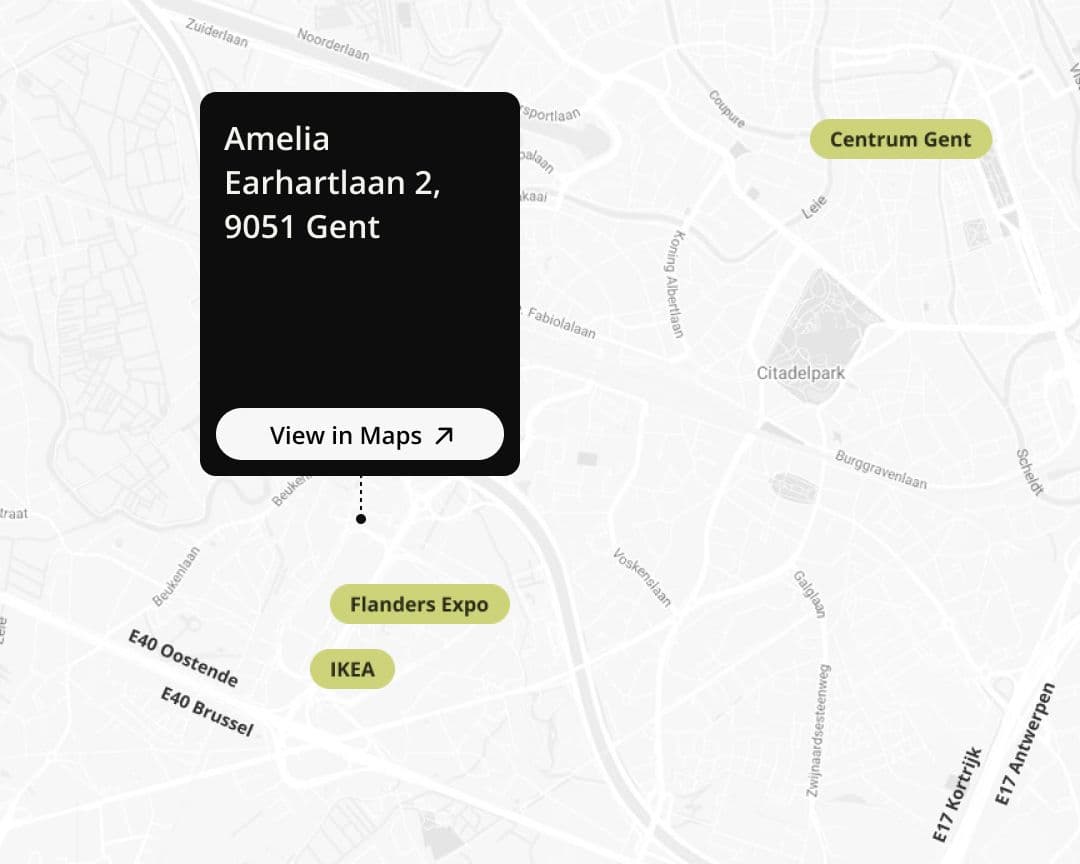

Alternatively, reach us at: